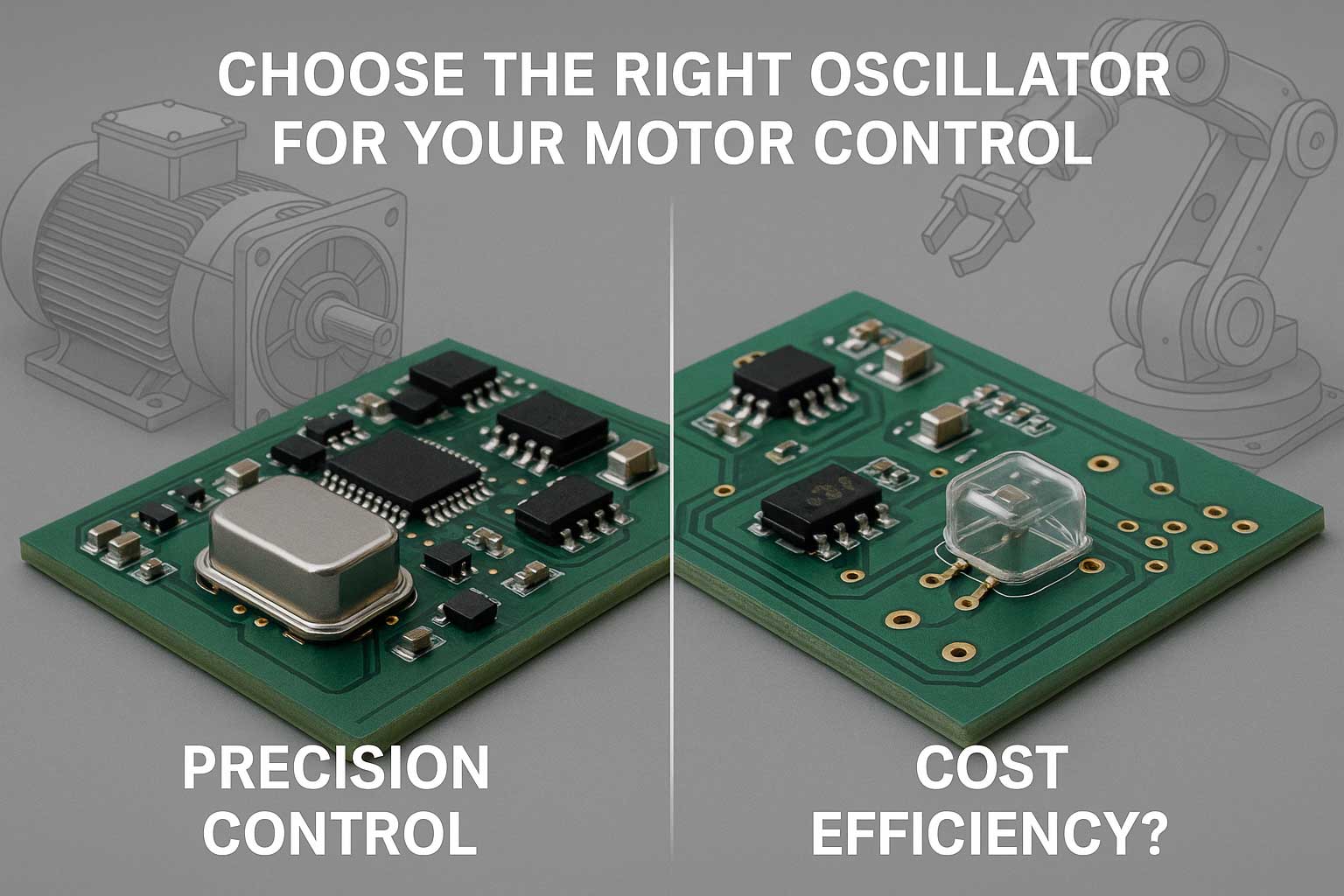

Active vs. Passive Crystal Oscillators: Which Is Right for Your Motor Driver Board?

In motor driver control systems, the crystal oscillator acts as the timing heartbeat — directly affecting PWM waveform generation, communication synchronization, and system stability. One important decision for engineers is whether to use an active oscillator or a passive crystal.

Passive Crystals: Cost-Effective but Circuit-Dependent

Passive crystals are quartz resonators that require an external oscillator circuit (usually built into the MCU or clock IC) to generate a clock signal. They are compact, energy-efficient, and cost-effective — ideal for basic motor control applications.

However, they rely heavily on external circuit design, offer limited startup performance, and are less stable in environments with strong electromagnetic interference (EMI).

Active Oscillators: Ready-to-Use, Highly Stable

Active crystal oscillators integrate the oscillation circuit within the package, delivering clean clock outputs directly. They provide superior frequency stability, low phase jitter, and are ideal for high-performance motor systems such as servo motors, BLDC motors, and stepper motors.

Especially in industrial automation where precision and stability are critical, active oscillators (e.g., TCXO) outperform passive counterparts.

Which to Choose?

|

Recommended Type | |

| Cost-sensitive, basic motor control | Passive Crystal | |

| High-precision PWM, synchronized multi-motor systems | Active Oscillator | |

| Ultra-compact PCB layouts | Passive Crystal (SMD) |

JGHC Recommended Models:

Whether you're building smart fans or robotic automation, the right crystal oscillator can make all the difference.

ontact us for samples and datasheets – and bring precision to your motor control systems!