What is the reason of failure of crystal oscillators?

Jan 08, 2025

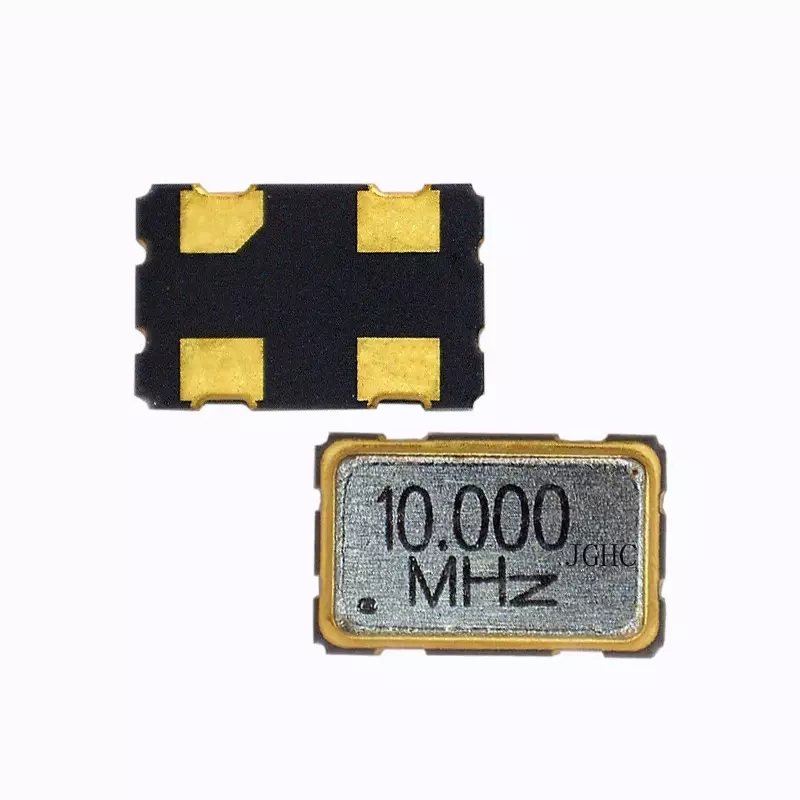

Crystal oscillators are crucial components in electronic circuits, providing accurate and stable frequency references for various devices, including computers, communication systems, and industrial equipment. Despite their reliability, crystal oscillators can fail under certain conditions, leading to issues such as vibration stop, waveform abnormality, and frequency drift.

Common Failure Modes of Crystal Oscillators

Crystal oscillators typically experience three primary failure modes:

Vibration Stop: Vibration stop occurs when the crystal's oscillation ceases altogether. This failure mode can result in the complete malfunction of the circuit relying on the oscillator. It is often caused by external shocks, excessive mechanical stress, or environmental factors such as extreme temperature variations.

Waveform Abnormality: Waveform abnormalities include distorted, unstable, or noisy output signals. These issues can lead to incorrect or erratic performance in the systems using the oscillator. Causes of waveform abnormalities include power supply noise, aging of components, and contamination within the oscillator housing.

Frequency Drift: Frequency drift refers to the gradual deviation of the oscillator's output frequency from its specified value. This can compromise the accuracy of timekeeping, signal synchronization, and data transmission. Frequency drift is often caused by thermal effects, aging of the crystal, or variations in load capacitance.

Failure Mechanisms and Root Causes

Crystal oscillators fail due to several mechanisms, many of which are linked to process defects. Below are the key failure mechanisms:

Chip Process Defects:

The semiconductor chip within the oscillator can exhibit defects introduced during fabrication. Common issues include:

Impurities or inconsistencies in the crystal material.

Poor adhesion between layers, leading to delamination.

Electrical shorts or opens due to contamination or lithography errors.

These defects can cause intermittent operation, increased phase noise, or total failure.

Module Packaging Process Defects:

Packaging defects can compromise the structural integrity and environmental protection of the oscillator. Examples include:

Inadequate sealing of the package, allowing moisture or contaminants to enter.

Stress-induced fractures or cracks in the housing.

Insufficient thermal management, leading to overheating.

Packaging-related failures can manifest as sudden breakdowns or long-term performance degradation.

Crystal Process Defects:

The piezoelectric crystal itself is prone to defects arising during its manufacturing. Key issues include:

Micro-cracks or voids in the crystal structure.

Inhomogeneous doping levels, affecting the crystal's resonant properties.

Contaminants on the crystal surface, altering its frequency characteristics.

These defects can lead to unpredictable behavior, such as frequency hopping or reduced Q-factor.

Environmental and Operational Factors

In addition to process defects, environmental and operational factors significantly impact the reliability of crystal oscillators:

Temperature Extremes:

Crystal oscillators are sensitive to temperature fluctuations. High temperatures can accelerate aging, while low temperatures may reduce the oscillator's drive level, causing frequency instability.

Mechanical Stress:

Vibrations, shocks, and mechanical stress can damage the crystal or its mounting, leading to vibration stop or frequency deviations. Proper mechanical design and shock-absorbing materials are essential to mitigate these effects.

Contamination:

Dust, moisture, or chemical contaminants can infiltrate the oscillator housing, affecting its electrical properties and leading to waveform abnormalities or total failure.

Aging:

Over time, the performance of a crystal oscillator naturally degrades. Aging effects include frequency drift, reduced output amplitude, and increased phase noise. Regular calibration and maintenance can minimize the impact of aging.

Preventive Measures and Best Practices

To enhance the reliability of crystal oscillators, several preventive measures can be implemented:

Improved Manufacturing Processes:

Use high-purity materials and advanced fabrication techniques to minimize defects.

Implement stringent quality control measures to identify and address defects early.

Robust Packaging:

Employ hermetically sealed enclosures to protect against moisture and contaminants.

Design packages to withstand mechanical stress and temperature extremes.

Environmental Control:

Use temperature-compensated crystal oscillators (TCXOs) or oven-controlled crystal oscillators (OCXOs) in environments with significant temperature variations.

Avoid exposing oscillators to excessive vibrations or shocks.

Regular Maintenance:

Periodically inspect and calibrate oscillators to ensure they meet performance specifications.

Replace aging components before they reach the end of their useful life.

Applications of Crystal Oscillators and Long-Term Reliability

Crystal oscillators are used in a wide range of applications, including telecommunications, GPS systems, and medical devices. Long-term reliability is critical in these fields to prevent system failures and ensure consistent performance. Employing high-quality oscillators and adhering to best practices in circuit design can significantly improve reliability.

Additionally, advancements in material science and manufacturing technologies are continually enhancing the performance and durability of crystal oscillators. For instance, the development of microelectromechanical systems (MEMS) oscillators offers promising alternatives with improved resistance to environmental factors and mechanical stress.

Crystal oscillators, while reliable, are not immune to failure. Common failure modes such as vibration stop, waveform abnormality, and frequency drift arise from process defects, environmental factors, and operational stress. Understanding these failure mechanisms and adopting preventive measures can significantly enhance the performance and longevity of crystal oscillators. By prioritizing quality manufacturing, robust packaging, and regular maintenance, engineers can ensure the reliable operation of crystal oscillators in critical applications. Shenzhen Jingguanghua Electronics will bring you safe, reliable and high-quality crystal oscillator products. You can go to our website to check the product model you need and send it to us or tell us your requirements. We will provide you with the most professional solution.

Read More