What are Crystal Oscillators Used for in Satisfactory?

Jul 16, 2025

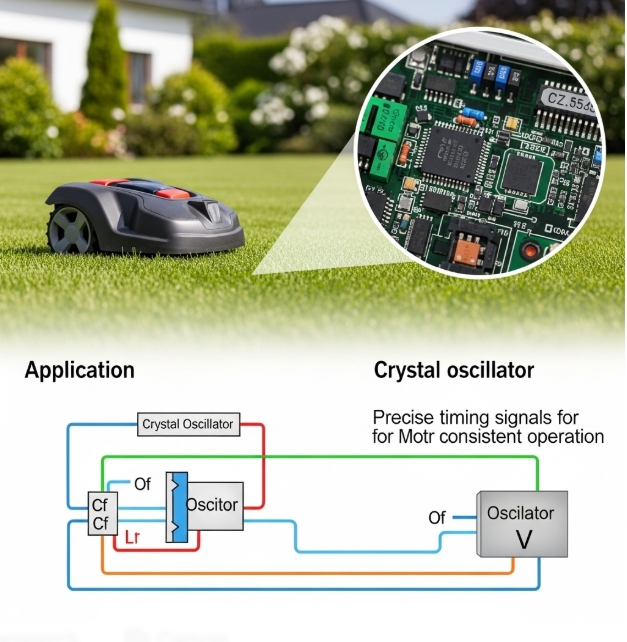

In advanced smart garden systems and autonomous outdoor machinery like electric lawnmowers and robotic gardening devices, crystal oscillators play a vital yet often overlooked role. These precision components are essential for maintaining synchronized communication, reliable signal processing, and stable timing in environments where vibration, temperature fluctuations, and moisture are inevitable. In the context of industrial-grade or consumer-grade satisfactory performance for outdoor automation, the role of oscillators extends far beyond basic clock generation.

Precision Timing in Harsh Environments

Crystal oscillators serve as the timing backbone for embedded systems, microcontrollers, and wireless communication modules used in robotic lawnmowers and automated garden machines. These devices often operate under direct sunlight, in fluctuating weather, or on rough terrain, requiring clock components that can function reliably across wide temperature ranges, typically from -40°C to +85°C or even higher. Standard oscillators may drift or fail under such conditions, leading to disrupted operations, signal errors, or uncoordinated motion control.

For instance, in brushless DC motors (BLDCs) used to drive the wheels or cutting blades of smart garden robots, precise pulse-width modulation (PWM) control is necessary. This is only possible if the oscillator stability remains intact despite environmental stress.

Vibration Resistance and Mechanical Reliability

Unlike indoor electronics, outdoor robotics such as autonomous mowers are constantly exposed to mechanical shock and vibration. When cutting grass or navigating uneven terrain, vibrations can interfere with sensitive timing circuits. Vibration-resistant crystal oscillators, often constructed with ruggedized ceramic or metal packages and epoxy-sealed joints, are engineered to minimize mechanical resonance that would otherwise cause timing jitter or data corruption.

These oscillators typically follow stringent MIL-STD-202 or AEC-Q200 testing protocols to ensure operational integrity in mobile or semi-industrial systems. Their mechanical resilience contributes directly to the long-term satisfactory performance and operational lifespan of smart gardening devices.

Moisture Protection and Long-Term Reliability

Outdoor automation must also contend with high humidity, rainfall, or dew accumulation. Moisture intrusion is a silent killer for electronic circuits, especially those responsible for high-frequency signal integrity. To address this, moisture-resistant crystal oscillators with hermetic sealing or advanced conformal coatings are preferred. These protective features prevent condensation from interfering with the quartz element’s vibration or shorting internal circuits.

In embedded RF modules used for Wi-Fi, Bluetooth, or proprietary communication systems, a moisture-compromised oscillator could lead to packet loss, unstable connections, or reduced range. Therefore, environmental protection in oscillator packaging is not just a matter of durability but also a prerequisite for uninterrupted connectivity.

Synchronization in Multi-Sensor Systems

Electric gardening robots often integrate multiple sensors—ranging from ultrasonic, LIDAR, GPS, to inertial measurement units (IMUs)—for autonomous navigation and object avoidance. These modules rely on tightly synchronized signals to calculate position, detect edges, or plan efficient mowing paths. Low phase noise crystal oscillators help maintain timing consistency across these modules, enabling real-time decision-making.

Without accurate frequency sources, sensor data fusion becomes unreliable, leading to behavior such as inaccurate mapping or inefficient path tracking—negatively affecting system performance.

Energy Efficiency and Signal Stability

In battery-powered robotic garden equipment, power consumption is a critical design constraint. Low-power crystal oscillators, such as temperature-compensated (TCXO) or micro-power variants, ensure that timing functions remain stable without significantly draining the battery. These oscillators are often used in real-time clocks (RTC) and sleep-wake cycles of the main control unit, allowing intelligent power management strategies to extend operational time between charges.

Moreover, maintaining signal stability over long periods helps avoid unnecessary recalibrations or software interruptions, contributing to the overall operational satisfaction of the end-user.

Crystal oscillators used in smart gardening equipment like electric lawnmowers and autonomous garden robots must meet demanding requirements in terms of temperature tolerance, vibration resistance, and moisture protection. Their role is foundational to ensuring signal integrity, synchronization, and energy efficiency in these mobile, outdoor platforms. As garden automation becomes increasingly sophisticated, the need for robust and high-precision timing components becomes even more crucial—making crystal oscillators indispensable for achieving long-term satisfactory performance in real-world applications.

Read More