What is the Application of Oscillator in Electronics?

Feb 12, 2025

Oscillators are fundamental components in electronic systems, providing stable frequency signals essential for numerous applications. Among various types, crystal oscillators play a critical role in AI computing power, ensuring precise timing and synchronization in high-performance computing environments. As AI-driven technologies demand ever-increasing processing speeds and efficiency, the role of crystal oscillators in enhancing computational reliability has become indispensable.

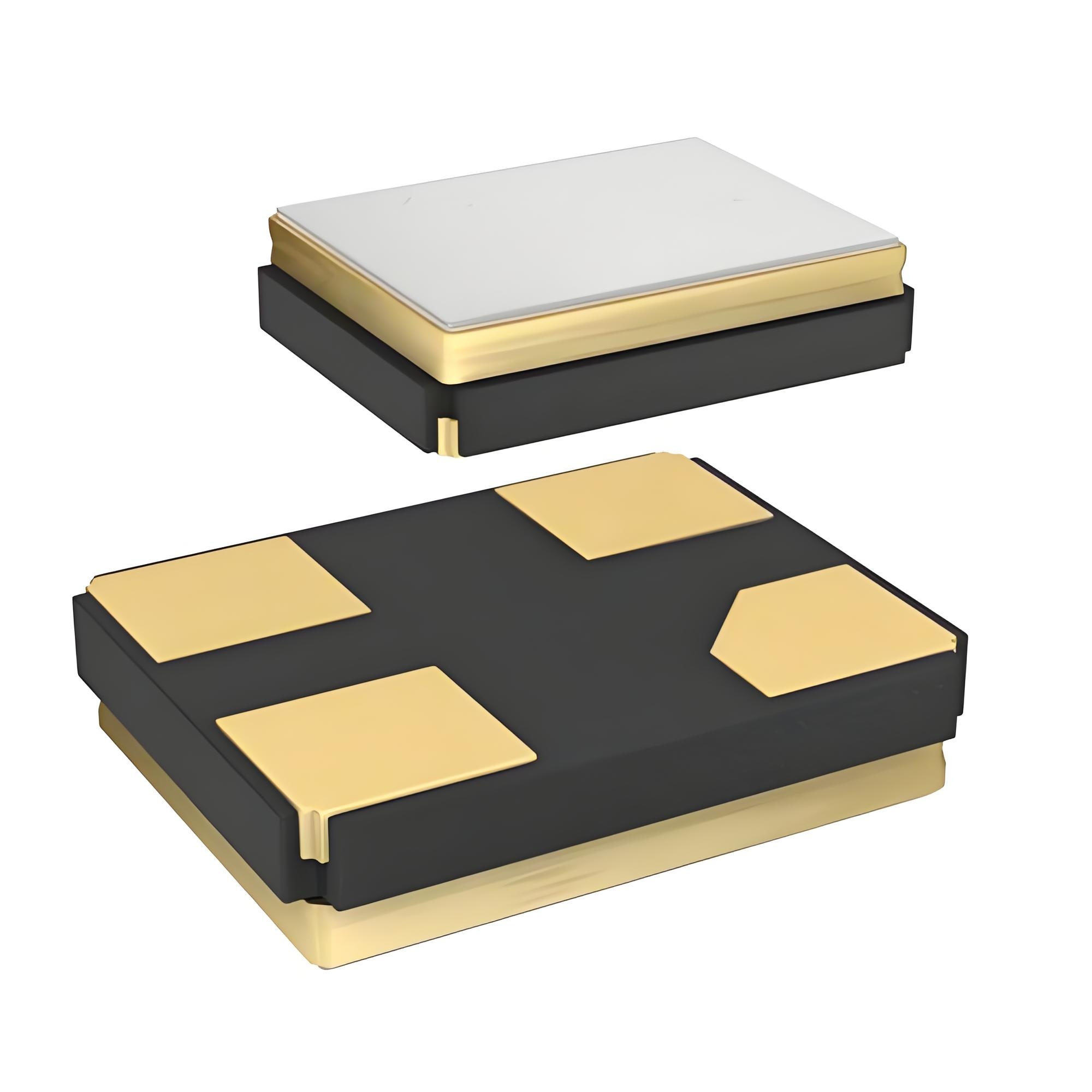

Fundamentals of Crystal Oscillators

Crystal oscillators operate based on the piezoelectric effect, wherein a quartz crystal generates a consistent oscillating signal when subjected to an electric field. These oscillators offer superior frequency stability, low phase noise, and minimal temperature drift compared to other timing solutions. Their reliability makes them the preferred choice in AI computing, data centers, and high-speed processors.

Role of Crystal Oscillators in AI Computing

1. Clock Synchronization in AI Processors

AI accelerators, including GPUs, TPUs, and ASICs, rely on synchronized operations for parallel processing. Crystal oscillators provide precise clock signals that help AI chips maintain coordination, reducing computational errors and latency. A stable clock source is crucial for neural network training and inference, ensuring consistent timing across millions of operations per second.

2. Enhancing Data Transmission in High-Speed Interfaces

AI computing systems require high-speed data transfer between processors, memory units, and external devices. Crystal oscillators play a vital role in maintaining data integrity in PCIe, Ethernet, and optical communication networks. Precise timing signals ensure minimal jitter and phase noise, optimizing signal processing efficiency in AI workloads.

3. Power Efficiency and Thermal Management

AI hardware consumes substantial power, generating significant heat during intensive computational tasks. High-performance oscillators contribute to power efficiency by reducing timing errors, which helps optimize processor workload distribution. Additionally, low-power crystal oscillators support energy-efficient AI edge computing, enabling battery-operated AI applications such as smart sensors and IoT devices.

4. Error Reduction in AI Model Training

AI model training involves iterative computations where even minor timing discrepancies can lead to propagation errors. High-precision crystal oscillators ensure stable timing references, reducing floating-point calculation inconsistencies and improving the reproducibility of AI models. This precision is particularly crucial in high-performance computing (HPC) clusters where distributed AI training takes place.

5. Stability in Quantum Computing and AI Synergy

As AI intersects with quantum computing, ultra-stable oscillators become essential for maintaining coherence in quantum processors. Crystal oscillators with extremely low phase noise support quantum AI applications by ensuring accurate signal generation for qubit manipulation and measurement.

Advancements in Crystal Oscillator Technology for AI

Temperature-Compensated and Oven-Controlled Crystal Oscillators

AI systems often operate in fluctuating temperature environments, requiring oscillators with robust thermal compensation. Temperature-Compensated Crystal Oscillators (TCXOs) and Oven-Controlled Crystal Oscillators (OCXOs) offer superior frequency stability, making them ideal for AI applications that demand long-term reliability.

Miniaturized and Low-Power Crystal Oscillators

The trend toward compact AI hardware necessitates miniaturized crystal oscillators with minimal power consumption. Advances in MEMS (Micro-Electromechanical Systems) technology have enabled the development of ultra-small, low-power oscillators that maintain high-frequency accuracy without excessive energy drain.

High-Frequency and Low-Phase-Noise Designs

AI workloads require ultra-fast processing speeds, prompting the need for high-frequency crystal oscillators with exceptionally low phase noise. Cutting-edge oscillator designs minimize signal distortion, improving AI algorithm execution speed and accuracy, particularly in deep learning applications.

Crystal oscillators play an indispensable role in AI computing power by ensuring precise clock synchronization, enhancing data transmission, optimizing power efficiency, and reducing computational errors. As AI technology evolves, the demand for high-performance, miniaturized, and energy-efficient oscillators will continue to grow. Innovations in oscillator technology will further strengthen AI-driven advancements, paving the way for next-generation computing architectures.

Read More