In advanced electronic drive systems, precise frequency control is the foundation of reliable operation. Oscillator circuits generate the timing signals that govern switching actions in power electronics, synchronize digital control units, and maintain steady communication between components. Without accurate oscillator performance, even well-designed motor drive systems can suffer from instability, increased losses, or reduced efficiency.

As motor technologies evolve, the requirements placed on oscillators have become increasingly demanding. In electric vehicle (EV) drive motors, switching frequencies must remain consistent under rapidly changing load conditions. Robotics and servo applications depend on precise oscillation to achieve exact positioning. Unmanned aerial vehicles (UAVs) require stable timing sources to maintain responsive motor control during flight. Similarly, industrial frequency inverters rely on oscillator circuits to regulate high-power motors with minimal harmonic distortion.

Motor control requires accurate timing signals to regulate voltage, current, and switching frequency. Even minor frequency drift can lead to inefficiencies, higher heat generation, or unstable operation. For example, in electric vehicle drive motors, the precise coordination between the inverter and motor ensures smooth torque delivery and higher energy efficiency. Oscillators serve as the backbone of this synchronization by providing stable clock references.

In robotics and servo motors, frequency stability directly affects positioning accuracy. Industrial robots executing repetitive tasks rely on synchronized control loops. A fluctuation in oscillator frequency may cause delays or errors, resulting in reduced precision. Similarly, servo systems that require microsecond-level accuracy depend on oscillators with low jitter and excellent temperature stability.

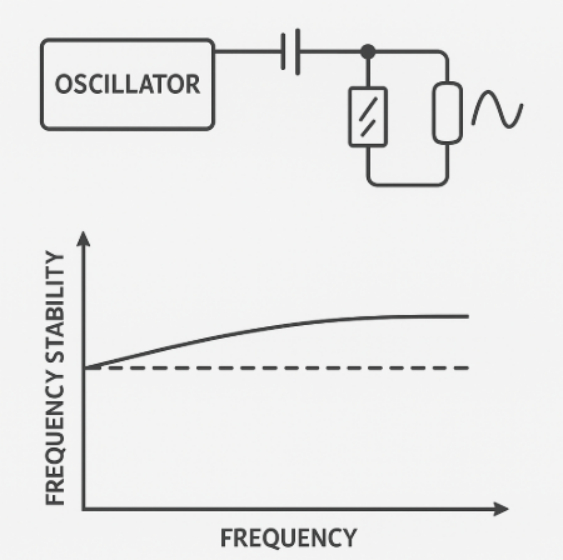

Crystal oscillators as the preferred solution

While various oscillator technologies exist, crystal oscillators are widely adopted in motor drive applications because of their superior stability. Quartz crystals exhibit a highly consistent resonance frequency, which is far less affected by temperature, vibration, or aging compared to LC oscillators or RC oscillators. This reliability makes them an essential component in demanding fields such as:

Unmanned aerial vehicle (UAV) motor control: where flight stability and navigation systems demand consistent timing references to avoid control instability.

Industrial frequency inverters: which regulate large motors in factories. These systems require oscillators that can operate accurately across wide temperature ranges while minimizing electromagnetic interference.

High-precision robotics: where every small deviation in frequency can influence servo accuracy and process efficiency.

Despite their inherent advantages, oscillators can still face challenges in maintaining frequency stability under real-world conditions. Key factors include:

Temperature variations – Wide environmental ranges, especially in automotive and outdoor applications, can shift oscillator frequency.

Mechanical stress and vibration – In UAVs and EVs, constant vibration can degrade timing accuracy.

Aging effects – Over long operational periods, crystal parameters gradually change, which can affect resonance frequency.

Power supply noise – Fluctuations in supply voltage may induce jitter or frequency instability.

Addressing these challenges requires careful design considerations and advanced oscillator technologies.

Several techniques are employed to enhance stability and ensure reliable motor drive performance:

Temperature-compensated crystal oscillators (TCXO): By integrating temperature sensors and compensation circuits, TCXOs minimize frequency drift across broad thermal ranges, making them suitable for EV inverters and outdoor robotics.

Vibration-resistant packaging: Specialized oscillator housings reduce sensitivity to mechanical shocks, enhancing reliability in UAVs and industrial machinery.

Low-jitter differential oscillators: Essential for servo control systems, these oscillators provide clean timing signals that support precise motion control.

Redundant oscillator designs: In safety-critical systems such as autonomous vehicles, dual or redundant oscillators ensure continuous operation even in case of failure.

Improving frequency stability in oscillator circuits is not simply a matter of enhancing component specifications; it is about enabling reliable, precise, and energy-efficient operation across diverse high-performance applications. From electric vehicles to industrial robotics and UAVs, crystal oscillators form the timing foundation that makes advanced motor control possible. As industries continue to demand higher precision and efficiency, further innovation in oscillator design—especially in temperature compensation, vibration resistance, and low-jitter performance—will remain essential to advancing the capabilities of modern electronic systems.